Dyness Knowledge | How to increase energy storage benefits in a market with internal competition

-

Technical Blog

-

2025-09-03

-

Dyness

Since 2025, we've noticed a rapid surge in demand for commercial and industrial energy storage overseas. Behind-the-meter energy storage systems (including both household and commercial energy storage) not only save customers electricity bills through peak-valley arbitrage but also serve as complementary storage for photovoltaic power generation, improving PV utilization and reducing curtailment. Some commercial and industrial energy storage systems in Europe and the United States can also participate in power trading, forming virtual power plants to generate additional revenue, and as a flexible resource, contribute to smoothing grid fluctuations and maintaining power balance.

Whether for end-users or EPC, the goal of energy storage projects is to generate ultimate returns, which is the ultimate value of industrial and commercial energy storage projects. However, factors influencing the profitability of industrial and commercial energy storage projects involve multiple aspects, including technology, market, policy, and operational management, requiring systematic analysis and targeted optimization. The following are key factors:

1. Electricity price mechanism and market policy factors

Peak-valley price differences determine arbitrage opportunities; a narrowing spread reduces returns. The strength of policy subsidies determines the speed of payback. For example, favorable European subsidy policies, combined with equipment rebates and power generation subsidies, can achieve a payback period of approximately four years, with an IRR exceeding 15%, making the project highly valuable. To address these influencing factors, Dyness has optimized its EMS energy management system. By dynamically adjusting operational strategies and optimizing charging and discharging strategies based on electricity pricing policies, it maximizes profits. It can also participate in multiple markets and combine ancillary services (such as frequency regulation and reserve capacity) to generate additional revenue.

2. Initial investment and cost factors

The initial project investment consists of equipment costs, operations and maintenance costs, and design and construction costs. Equipment costs account for the largest portion (80%), followed by design and construction costs at 15%, and operations and maintenance costs at 5%. As a provider of energy storage equipment, Dyness adheres to the principle of in-house research, production, and sales, striving to provide customers with cost-effective energy storage products. Dyness boasts advantages in supply chain management and manufacturing. While ensuring product safety, reliability, and stable operation, it offers customers cost-effective products.

3. Product performance and reliability

In the profit calculation model, product parameter performance determines the payback period and total profit, mainly including the following points.

System Efficiency: Higher system efficiency means more actual system discharge, greater peak-valley arbitrage profits, and thus impacts the overall project payback period and IRR. System efficiency is calculated as the system discharge divided by the system charge. Currently, most energy storage systems on the market have an efficiency of around 84% to 88%, primarily affected by the system's auxiliary power supply, water chiller power supply, and heat loss. In the future, Dyness will optimize its auxiliary power supply and intelligent temperature control to reduce power consumption in the internal power distribution system, thereby improving system efficiency, achieving a faster payback period, and increasing IRR.

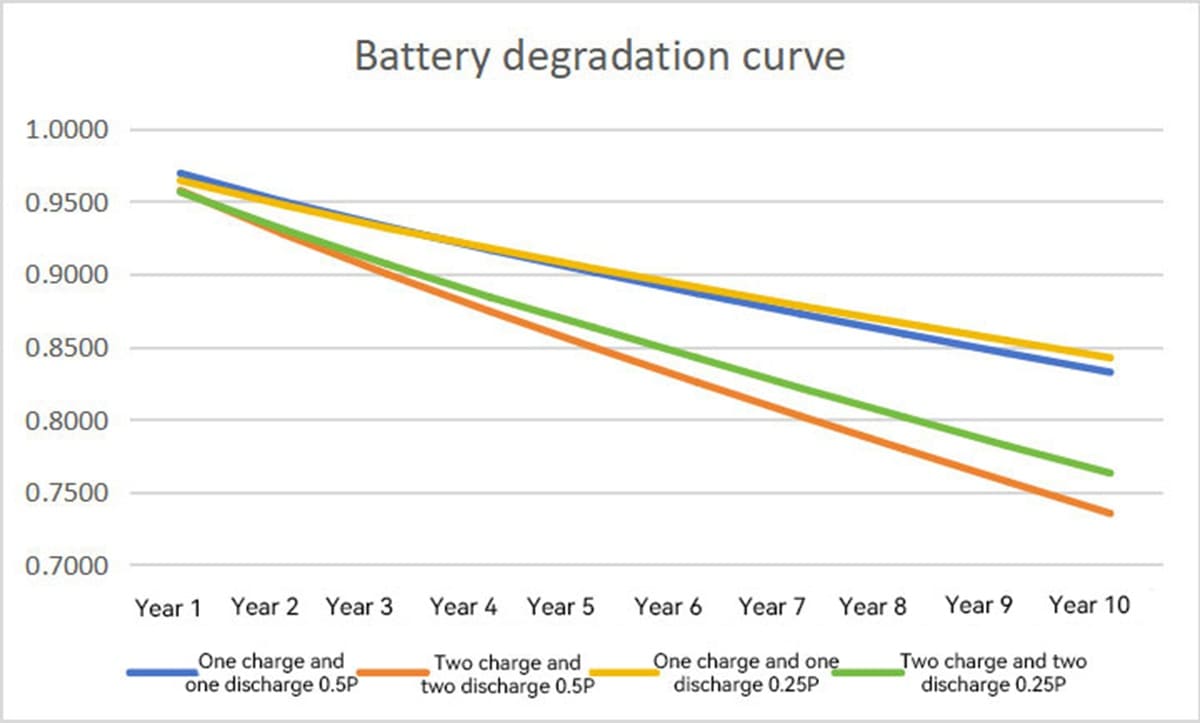

Battery lifespan and degradation rate: During actual project operation, batteries must be replaced after their capacity has degraded to 80%, otherwise their lifetime revenue will be impacted. A Class A battery typically has a service life of 6,000 cycles at 80% SOC @ 0.5CP/25°C or 10 years at 80% SOC, whichever comes first. Factors influencing degradation rate include cell brand, charge/discharge rate, operating temperature, and operating strategy. Different cell brands have varying degradation rates. Faster degradation means less actual power generation over the project's lifespan, significantly impacting payback period and profitability. Dyness Industrial and Commercial Storage products utilize Class A cells. The system supports a maximum charge/discharge rate of 0.5CP. An internal temperature control system ensures stable battery operation at an optimal ambient temperature of 25°C. Furthermore, through the use of AI data models, EMS strategies are intelligently adjusted, enabling the system to operate at lower rates and slower charge/discharge rates based on electricity price periods, thereby mitigating battery degradation.

System depth of charge/discharge (DOD): DOD is equal to the charge or discharge capacity divided by the rated capacity. Energy storage systems typically operate at 90% DOD. Increasing DOD can help increase system discharge capacity, thereby improving project profitability. This aspect primarily depends on the cell's process and performance. Excessively high DOD can also affect the battery's cycle life, though this may improve with future advancements in cell technology.

Energy density: Some projects could actually be configured with a larger capacity, but due to limited on-site construction area, they are forced to configure a smaller capacity. This impacts the total revenue of the energy storage project and reduces the IRR ratio, highlighting the importance of increasing product capacity density. Currently, the main approach is to use large single-cell batteries for AC/DC integrated cabinets, which achieves higher integration and a smaller equipment footprint. Alternatively, the cooling airflow can be modified. A full liquid cooling system with forward-facing, upward-exhaust ventilation allows devices to be placed back-to-back, improving land utilization and preventing the need for more energy storage equipment.

Environmental adaptability: Currently, demand for commercial energy storage is strong overseas, but operating environments are often harsh. For example, the Middle East and Africa experience year-round high temperatures, reaching as high as 50°C. This can easily lead to equipment overheating alarms and failures, impacting project returns and increasing O&M costs. Furthermore, these regions are prone to high levels of dust and sand, which can easily enter equipment and cause system failures. Some countries are located in plateau areas, with altitudes of approximately 2,000 to 4,000 meters. This can cause system power derating, impacting project returns. Therefore, environmental adaptability is a high requirement for equipment. Projects in these regions require high-performance energy storage systems with strong protection, corrosion resistance, and no derating at high temperatures to cope with these harsh environments.

4.The degree of matching energy storage configuration with load

Over-configuration of capacity can result in excessive initial equipment costs, impacting payback periods and overall profits; under-configuration can significantly reduce the project's ultimate returns. Currently, some projects in the market have over-configured capacity due to poorly defined configuration requirements in pre-sales proposals. This leads to wasted capacity during actual operation, resulting in insufficient energy consumption, increased equipment costs, and reduced overall returns. For example, domestic projects primarily focus on peak load shaving and valley filling, requiring the energy storage system to achieve 100% absorption, with two charges and two discharges per day, to maximize returns. Initial load analysis should consider the stability of the monthly and daily load curves, striving to ensure 100% absorption for approximately 330 days of the year. A relatively conservative approach to storage allocation ensures project reliability and investment value. Dyness specializes in developing distributed energy storage systems that support flexible expansion, allowing capacity to be expanded based on future load demands, avoiding waste caused by over-configuration.

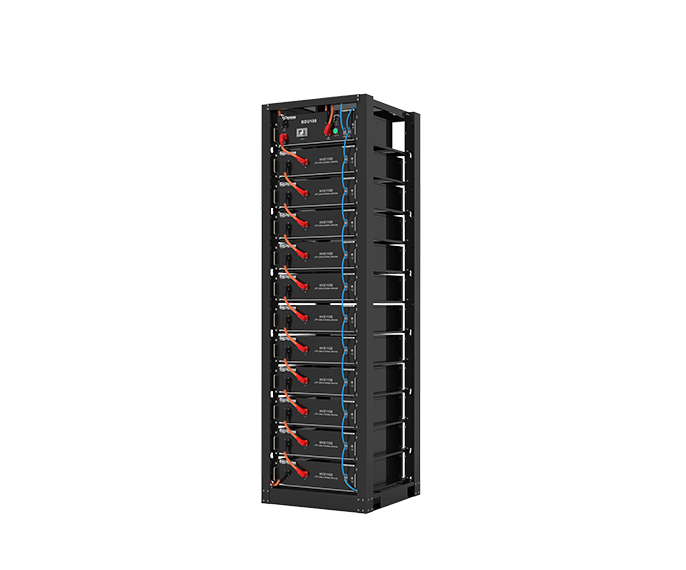

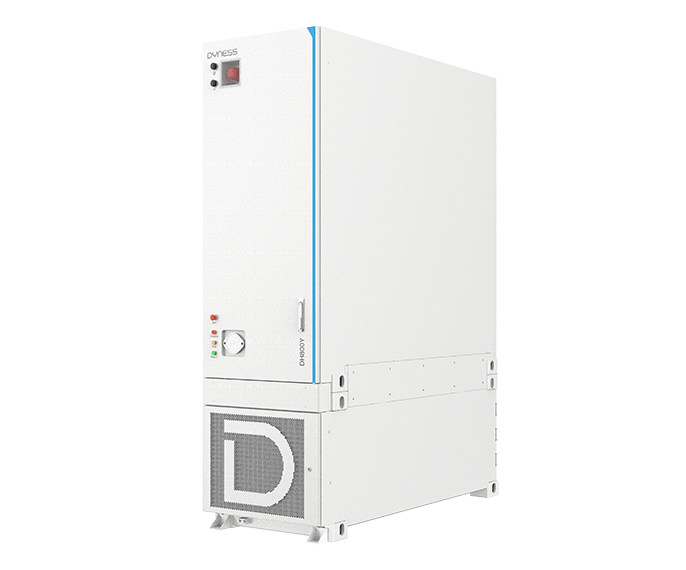

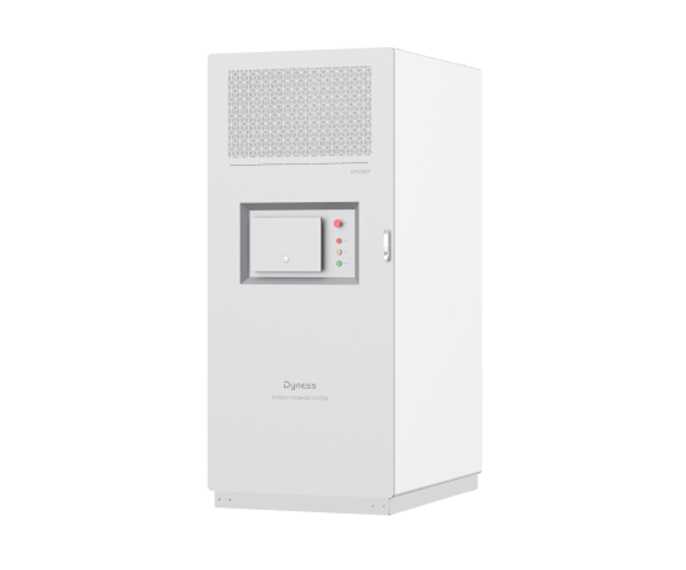

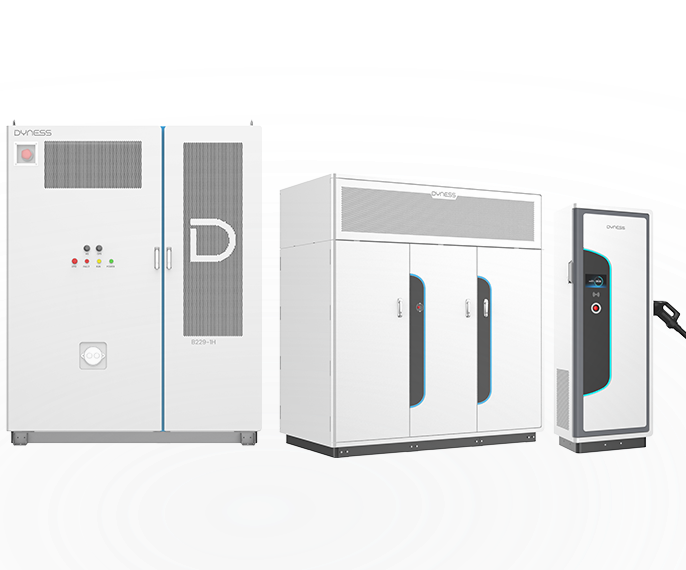

As a professional energy storage manufacturer, Dyness is committed to providing customers with high-quality products and services. In response to the above analysis of factors influencing energy storage returns, Dyness launched the DH800Y fully liquid-cooled energy storage system, covering a wide range of applications in both user-side and grid-side scenarios. The DH800Y is a new-generation fully liquid-cooled modular energy storage system, a 690V medium-voltage grid-connected solution with a single cabinet capacity of 836kWh and a maximum efficiency of 90%. It has a high protection level of IP55 and C4 (C5 optional). The battery and PCS adopt a fully liquid-cooled design and can operate without derating in an ambient temperature of 50°C. The system uses large 314Ah cells, achieving a system energy density exceeding 103kWh/m³, a 30% increase compared to similar energy storage systems, and a 35% reduction in footprint, helping customers reduce site construction costs and shorten the payback period.

Dyness Digital Energy Technology Co., LTD

WhatsApp: +86 181 3643 0896 Email: info@dyness-tech.com

Address: No.688, Liupu Road, Suzhou, Jiangsu China

Dyness Website: https://www.dyness.com/

Dyness community: https://www.facebook.com/groups/73560020090