Dyness Knowledge | Common faults and maintenance methods of home energy storage batteries (1)

-

Technical Blog

-

2024-01-18

-

Dyness

This article will briefly introduce some common fault characteristics, causes, and maintenance methods.

As the simplest and most convenient product in the energy storage industry, many customers love and respect lithium-ion batteries. However, there will be some failures in the daily installation and use process. In addition to the impact of manufacturing quality, transportation, and storage, most of them are caused by improper maintenance. This article will briefly introduce some common fault characteristics, causes, and maintenance methods.

Thermal fault - operating environment

1. The necessity of thermal management

During lithium batteries' charging and discharging process, part of the chemical or electrical energy will be converted into heat energy. If the heat dissipation effect of the energy storage system is not good, it may lead to thermal runaway, which will cause short circuits, bulging, and open flame problems of the battery, which may eventually lead to safety accidents such as fire or explosion.

On April 16, 2021, a fire and explosion at the Dahongmen Energy Storage Power Station in Beijing killed one electrician on duty, two firefighters died, and one firefighter was injured.

On February 13, 2022, the world's largest Moss Landing lithium-ion energy storage station facility, owned by Vistra Energy in California, triggered a fire alarm due to the complete melting of 10 battery packs.

2. Thermal management solution measures

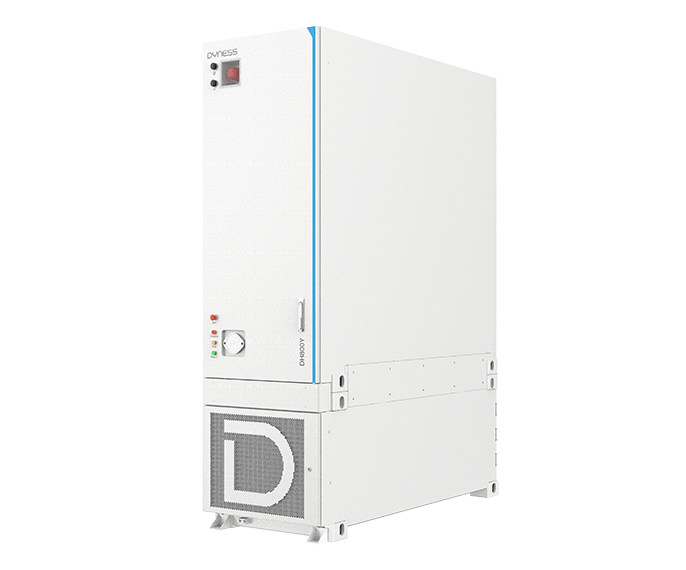

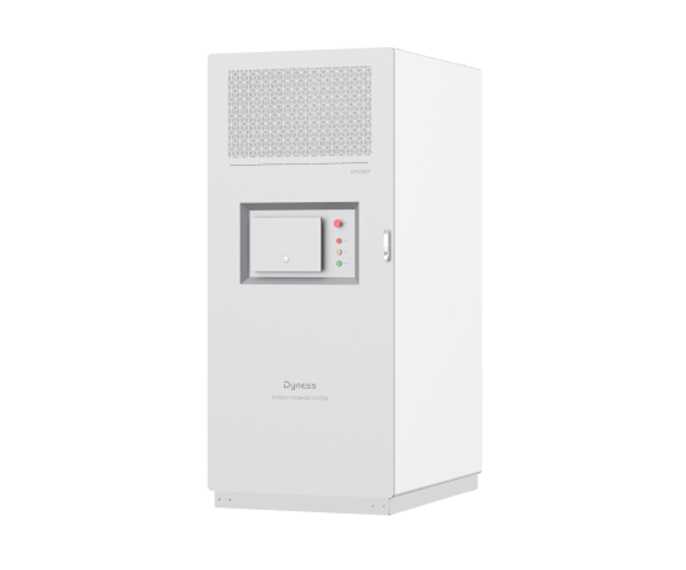

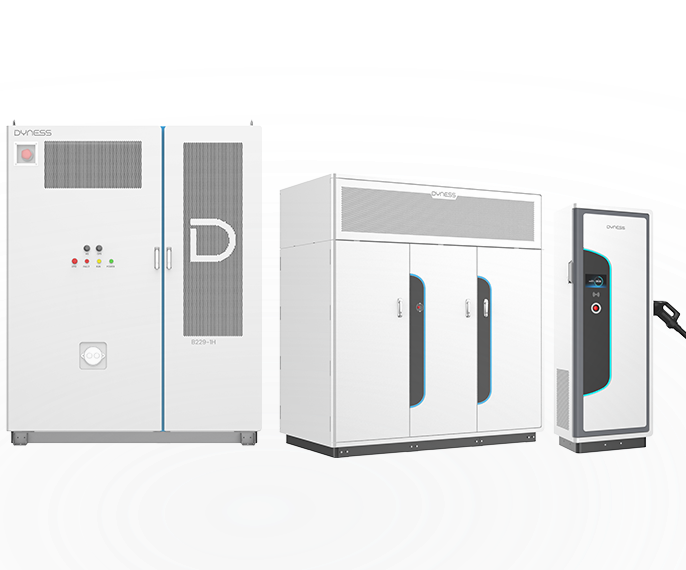

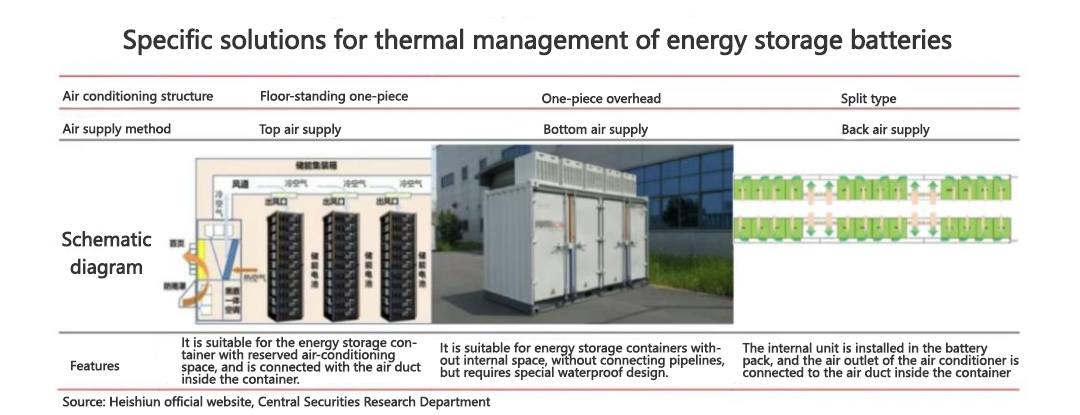

Air-cooled technology: There are many different structural design schemes for air-cooled thermal management systems. The structure of the air conditioner includes a floor-mounted integrated type, a top-mounted integrated type, and a split type. The air supply mode includes top air supply, back air supply, bottom air supply, etc.

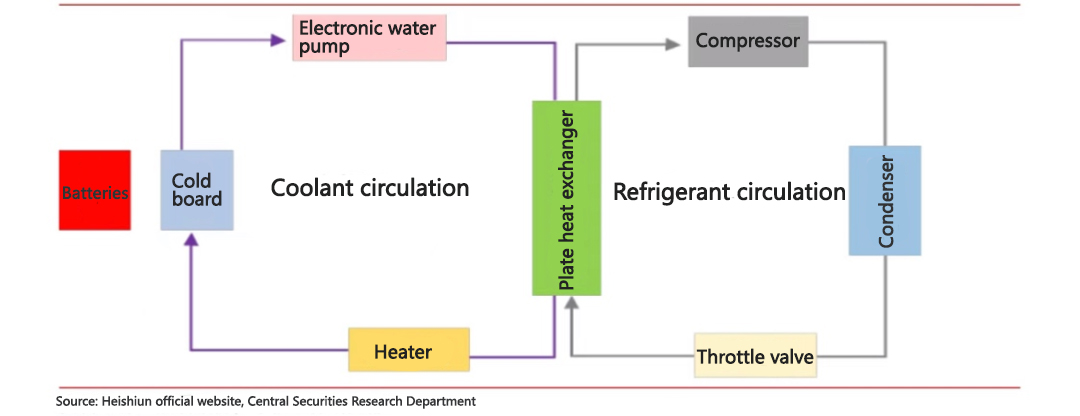

Liquid cooling technology: The liquid cooling solution has significant comprehensive advantages in ensuring the safety of the energy storage system and heat dissipation efficiency. The liquid cooling scheme uses cooling liquids such as water, ethanol, and silicone oil to dissipate heat through indirect contact between the evenly distributed flow guide grooves on the liquid cooling plate and the battery cells.

Electrical failure - overcharge or overdischarge

1. The hazards of battery overcharge and overdischarge

Overcharge: Overcharge means that when the lithium-ion battery is overcharged, the charging voltage exceeds the set voltage, such as the rated voltage of the battery is 3.7V, and the fully charged voltage is 4.2±0.05V. That is, the highest voltage is 4.25V, and it is called an overcharge if it exceeds 4.25V. When overcharging, the battery voltage rises rapidly with the increase of polarization, which will cause irreversible changes in the structure of the positive active material and the decomposition of the electrolyte, a large amount of gas will appear, and a large amount of heat will be released, which will cause a sharp increase in the temperature and internal pressure of the battery. The diaphragm melts or shrinks, causing the positive and negative materials to contact and short circuit, and there are hidden dangers such as explosion and combustion.

Over-discharge: Over-discharge means that the discharge voltage reaches the rated voltage and continues to discharge. For example, the rated discharge voltage of a ternary lithium-ion battery is 3.2V. If it is lower than 3.2V and continues to discharge, it is over-discharged. After the battery discharges the internal stored power and the voltage reaches a certain value, continuing to discharge will cause over-discharge. Over-discharge of the battery may bring disastrous consequences to the battery. bigger. Generally speaking, over-discharge will increase the internal pressure of the battery, destroy the reversibility of the positive and negative active materials, decompose the electrolyte, deposit lithium on the negative electrode, and increase the resistance. Even if it is charged, it can only be partially recovered, and the capacity will also decline significantly. .

2. Preventive measures for overcharge and over-discharge

1) Using a lithium-ion battery with a BMS management system, the protection board can protect the battery from overcharging or over-discharging, and can also communicate with the inverter to automatically set the correct charging and discharging parameter values, which can better protect the battery.

2) Correctly set the fast charging voltage, float voltage, and cut-off voltage of the inverter according to the battery parameters.

3) When the battery voltage reaches the voltage set by the protection board, the protection board will cut off the power to protect the battery, but the lithium-ion battery will fall back, and the voltage will rise, which will be a little higher than the voltage set by the protection board. At this time, it can no longer be used. Repeated use will cause irreversible damage to the battery.

Mechanical failure - installation environment

Before installing and using the energy storage lithium battery, you should carefully read the product technical manual and installation diagram, and install it as required. When installing, pay special attention to the following points:

1) The installation plan should be designed according to the location, area, and surrounding environment, such as ground load, ventilation environment, sunlight exposure, machine room layout, and easy maintenance. For batteries placed outdoors, special attention should be paid to objective factors such as waterproofing, sunscreen, and dustproof.

2) Different types of batteries or batteries of different capacities must not be mixed during installation.

3) Check the appearance of the battery before installation, the inspection items are whether there is leakage, whether the cover is damaged, and whether the open circuit voltage is normal. When handling the battery, be careful not to bump it, and do a good job of protection.

4) Batteries are shipped from the factory charged and must be handled carefully to avoid short circuits. Insulated tools and insulated gloves should be used during installation to prevent electric shock.

5) Before installation and use, the battery should be stored at -20-40°C. The storage period is 6 months (calculated from the date of delivery of the battery). If it exceeds 6 months, it must be 3.25V ℃) Constant voltage and current limiting 0.1C10A charging for 5h.

6) According to the installation diagram, connect the battery cables between columns, layers, and panel terminals. Before installing the terminal positive and negative connectors and conducting the entire power system, you should carefully check the positive and negative and measure the system voltage and set the battery parameter settings of the device at the same time. After the connection is completed, pay attention to covering the terminal and the protective sleeve of the connecting copper bar to prevent a short circuit.

7) When the energy storage lithium battery is connected, the screws must be tightened, but it is also necessary to prevent excessive tightening force from damaging the post-embedded copper parts or the lead-out terminals. At the end of the installation, check the system voltage and the positive and negative direction of the battery again to ensure that the battery is installed correctly.

8) After installation, use a clean dry soft cloth to clean the battery case, cover, panel, and connecting wires. Do not use organic solvents to clean, so as not to corrode the battery case cover and other components. At the same time, clean up the surrounding environment where the battery is installed, pay attention to ventilation, dustproof and waterproof.

Module difference capacity loss - series connection of high voltage system

For household low-voltage energy storage systems where new and old lithium batteries are mixed, the internal resistance of the batteries varies greatly, which is likely to cause circulation, and the temperature of the battery will increase, which will accelerate the aging of the new battery.

For household high-voltage energy storage systems, old and new battery modules are mixed in series. Due to the barrel effect, the new battery module can only be used with the capacity of the old battery module, and the battery cluster will have a serious capacity mismatch.

Abnormal battery SOC

① For regular maintenance, it is necessary to perform SOC calibration, capacity calibration, or main circuit inspection for the battery pack.

②When the battery module is abnormal, the conventional lithium battery does not have the automatic equalization function, and maintenance personnel need to go to the site to manually recharge the power, which cannot quickly respond to customer needs.