Dyness Knowledge | From Air Cooling to Liquid Cooling:The Evolution and Selection Strategies of Temperature Control Technologies for C&I Energy Storage Systems

-

Technical Blog

-

2026-01-08

-

Dyness

Air-cooled and liquid-cooled products each have their own advantages. Looking ahead, energy storage thermal management will evolve towards higher energy efficiency, smaller temperature differences, and integrated multi-thermal management, driving innovation in system-level solutions.

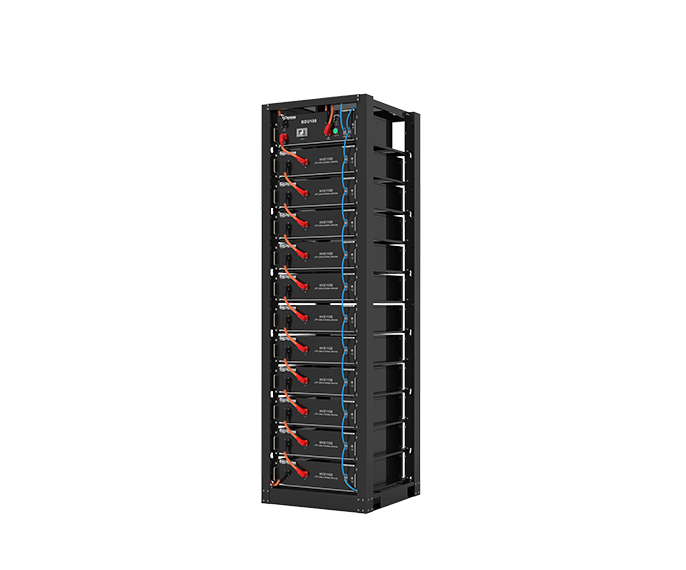

Traditional industrial and commercial energy storage cabinets typically employ a "fan + air conditioner" air cooling system, which refers to a temperature control scheme that combines active cooling by an air conditioner with forced circulation by a fan. The principle is that the air conditioning unit cools the air, and then the fan drives the low-temperature air to flow across the surface of the battery modules for forced convective heat transfer. The air, after absorbing heat, returns to the air conditioner through a return air duct for further cooling, forming a closed-loop temperature control cycle. The operating mode, start/stop conditions of the air conditioner, and the start/stop conditions of the fan are all controlled by software after sampling the battery cell and ambient temperatures.

As energy storage cells trend towards larger capacities, energy storage systems are entering the 5MWh+ era, with larger scale and higher energy density becoming the development trend for system integration. Simultaneously, the increasing diversification of application scenarios places higher demands on the lifespan, safety, and cost of energy storage systems. Against this backdrop, liquid cooling systems have emerged because liquids have significantly higher specific heat capacity and thermal conductivity than air. Currently, the industry mainly uses three types of liquid cooling: cold plate liquid cooling, direct cooling, and immersion cooling.

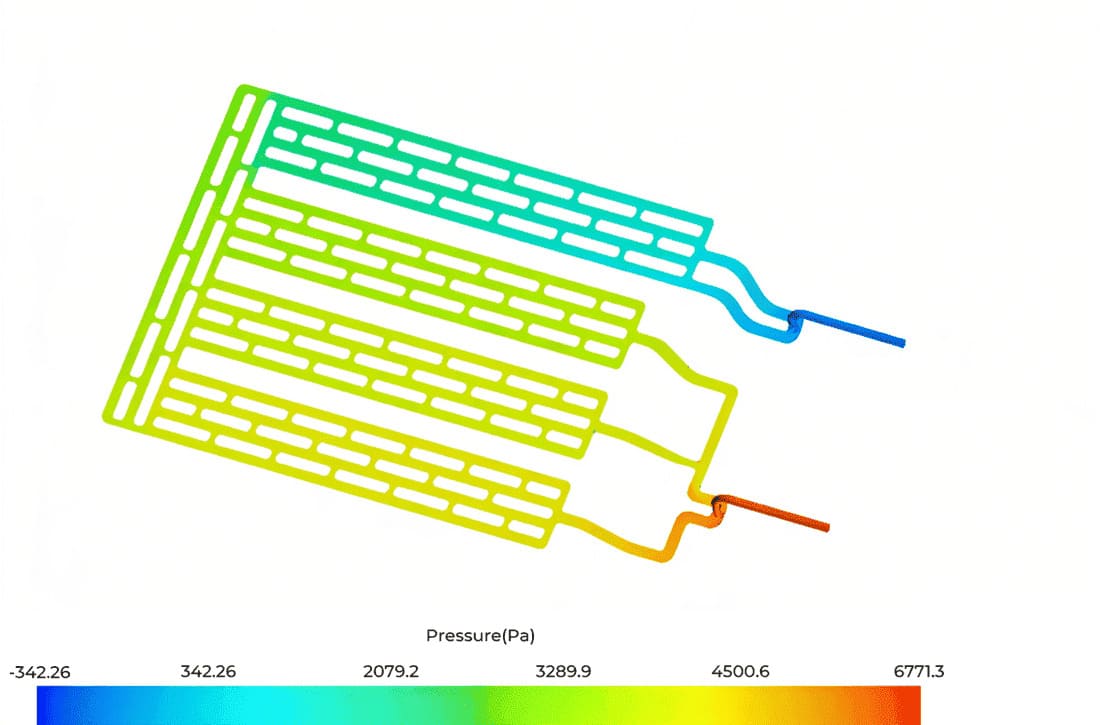

Cold plate liquid cooling

Cold plate liquid cooling refers to a temperature control method that uses a liquid as the cooling medium and achieves efficient heat exchange through direct contact between the liquid cooling plate and the battery. Its working principle is as follows: the coolant, driven by a pump, circulates within the flow channels of the liquid cooling plate, absorbing heat from the battery. The heated liquid then returns to the liquid cooling unit, where the heat is dissipated through a heat exchanger. The cooled liquid then recirculates, enabling precise temperature management of the battery. Compared to air cooling, cold plate liquid cooling offers higher heat dissipation efficiency, smaller battery temperature differences, lower noise levels, and is less susceptible to external environmental factors such as temperature and humidity. However, its procurement, installation, and ongoing maintenance costs must be considered, and there is also a potential risk of coolant leakage.

Direct cooling

The direct cooling design principle involves the rapid phase change and vaporization of the refrigerant, absorbing a large amount of heat energy. Compared to cold plate liquid cooling solutions, direct cooling excels in controlling battery temperature with its "fast," "precise," and "effective" characteristics. Therefore, the heat exchange efficiency of direct cooling technology is more than three times higher than that of cold plate liquid cooling solutions, especially when the battery is operating continuously at high power. Direct cooling ensures that the battery remains in a suitable temperature environment, and the absence of water pumps and circulation pipes results in lower system complexity and saves installation space. Although direct cooling technology is advanced, it requires high pressure resistance and sealing capabilities, and may lead to uneven battery temperature distribution. Uneven temperature distribution can affect battery consistency and shorten battery life.

Immersion cooling

Currently, an advanced liquid cooling method is emerging in the industry – immersion cooling. Immersion cooling involves completely submerging the battery in a highly thermally conductive cooling fluid. The cooling fluid directly contacts the battery surface, rapidly absorbing heat through thermal conduction. The heated fluid is then circulated to a heat exchanger, where the heat is released into the external environment. The cooled fluid then returns to the battery area, continuing the cooling cycle. Immersion cooling offers excellent temperature uniformity, and because the cooling fluid has good insulation and flame-retardant properties, it effectively combines temperature control and fire protection in a single design. However, the current raw material and maintenance costs are extremely high, and it requires strict battery sealing, thus limiting its widespread application.

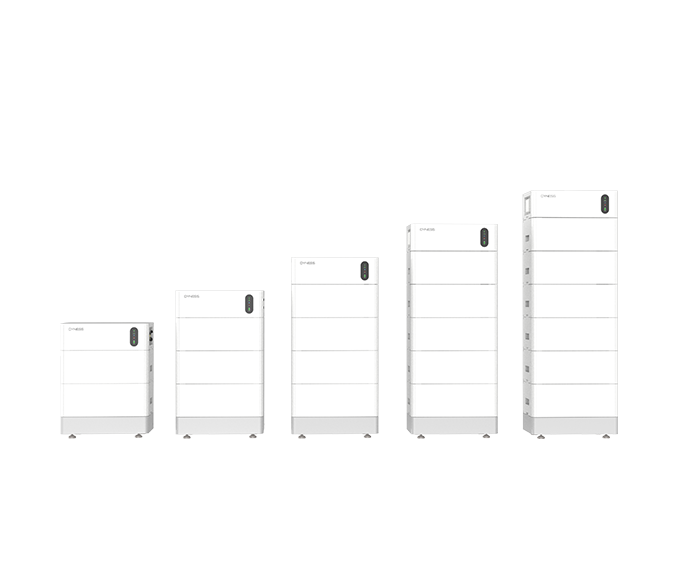

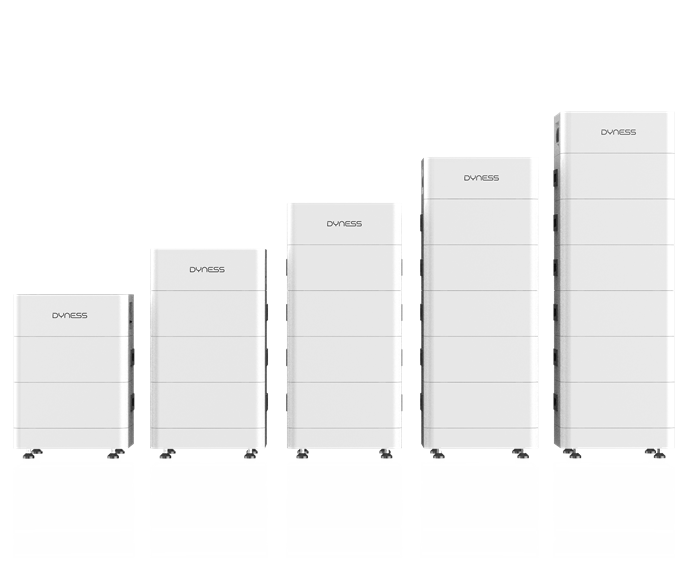

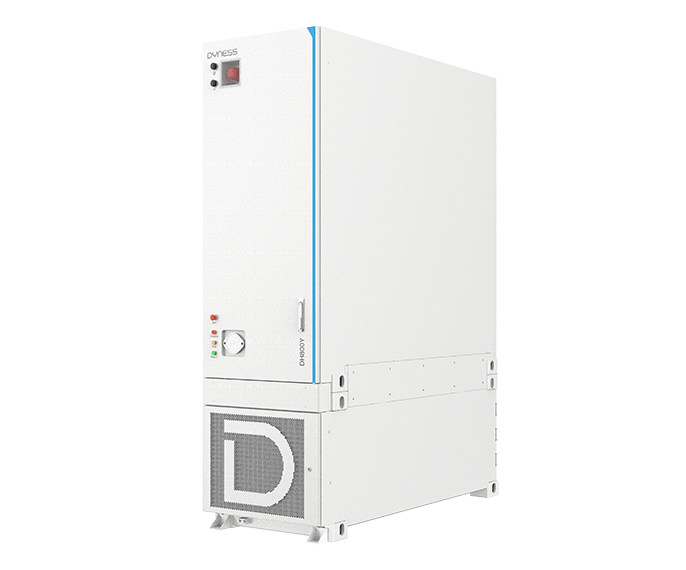

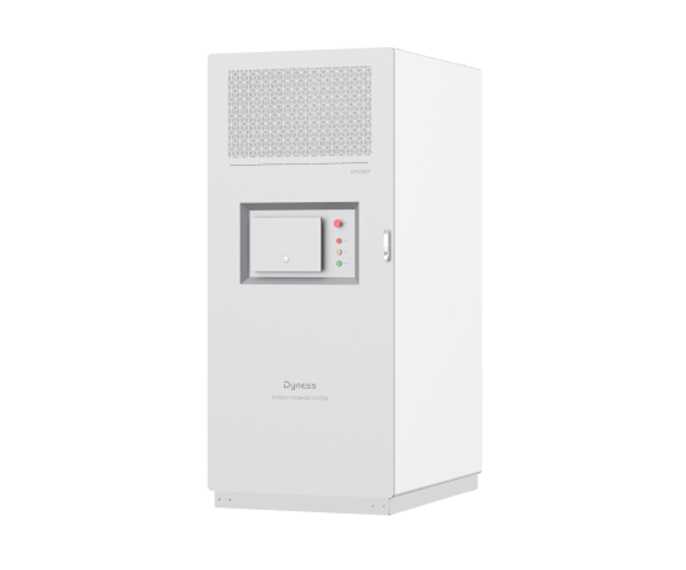

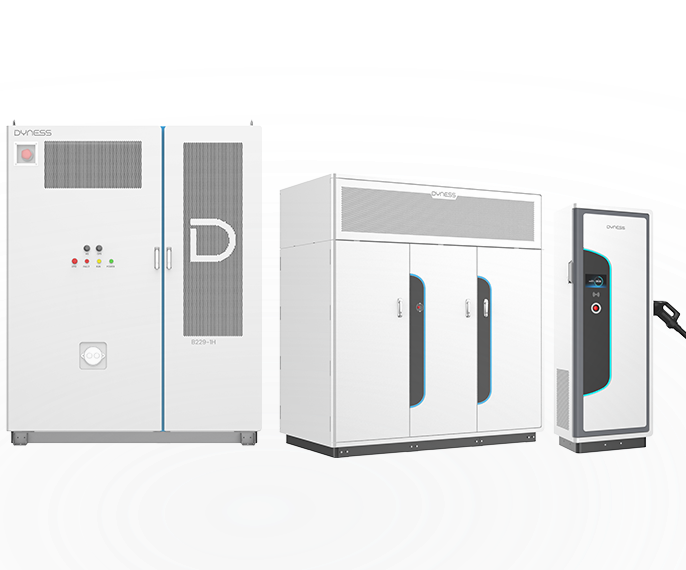

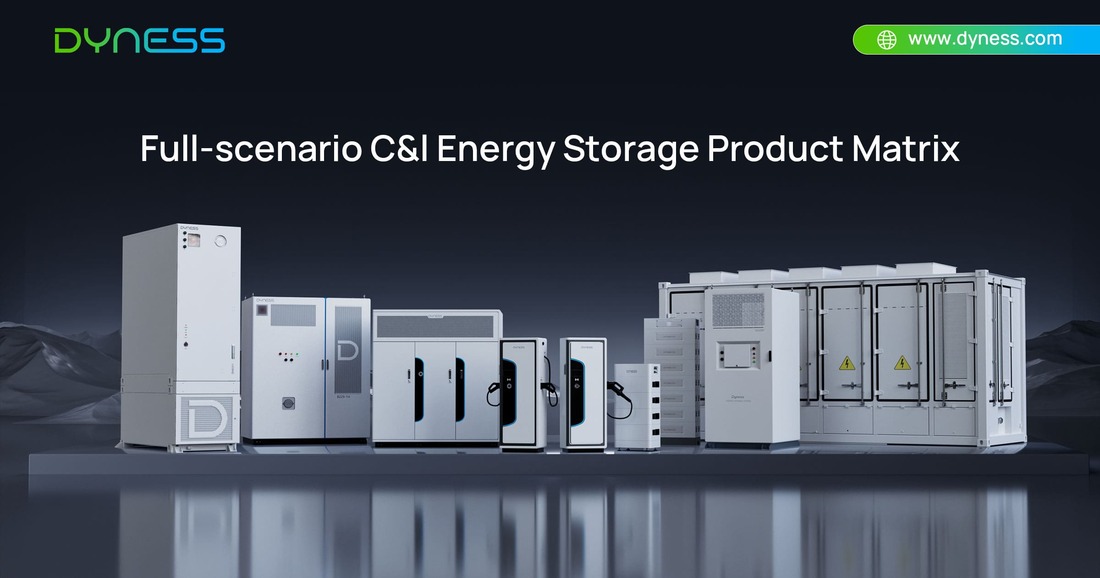

Commercial and industrial energy storage products of Dyness are divided into two main series: air-cooled and liquid-cooled. The air-cooled integrated solar-plus-storage system, represented by the DH200F, is highly favored by customers due to its application in all scenarios involving solar, storage, and diesel power. The liquid-cooled integrated cabinets for commercial and industrial energy storage, represented by the DH200Y and DH800Y, utilize a mature cold plate liquid cooling solution. The DH800Y product is a medium-voltage grid-connected, fully liquid-cooled (battery + PCS), modular energy storage system, ensuring high energy density while also incorporating a precise battery temperature control system. This guarantees battery consistency, extends battery life, and ensures the highest return on investment for users throughout the product's lifecycle. However, how to choose between air cooling and liquid cooling? Both air cooling and liquid cooling have their respective advantages and disadvantages, and the decision should be made based on actual application requirements and considering the following key dimensions.

1.Consider the project scale and space.

Choose air cooling: Suitable for small to medium-scale projects with ample installation space.

Choose liquid cooling: Suitable for medium to large-scale projects with limited space or those aiming to maximize land utilization. For example, in business parks or charging stations, solutions with high capacity per cabinet and a small footprint are required.

2.Consider the operating conditions and revenue requirements.

Air cooling is suitable for scenarios with gradual charging and discharging strategies, moderate peak-to-off-peak price differences, and where high long-term cycle life is not a primary requirement.

Liquid cooling is suitable for scenarios with high charge/discharge rates, frequent charging and discharging (such as two charges and two discharges per day), large peak-to-off-peak price differences, and where maximizing lifetime profitability is the goal. Its superior temperature control ensures stable operation under high intensity conditions and extends the system's lifespan.

3. Consider the investment budget and operational capabilities.

Choose air cooling: if you have a limited initial budget and prefer simple operation and maintenance, and want to minimize reliance on professional maintenance teams.

Choose liquid cooling: if you are willing to accept higher initial investment but expect to offset the cost through a longer lifespan and higher returns, and have access to professional maintenance capabilities or service channels.

4. Check the installation environment.

Choose air cooling: Suitable for outdoor or indoor environments with mild climate, clean air, and no extreme weather conditions.

Choose liquid cooling: Suitable for harsh environments such as those with high temperature, high humidity, dust, or coastal areas with high salt spray, or for locations where noise sensitivity is a concern.

In general, air-cooled and liquid-cooled products each have their own advantages. Looking ahead, energy storage thermal management will evolve towards higher energy efficiency, smaller temperature differences, and integrated multi-thermal management, driving innovation in system-level solutions.

Dyness Digital Energy Technology Co., LTD

WhatsApp: +86 181 3643 0896 Email: info@dyness-tech.com

Address: No.688, Liupu Road, Suzhou, Jiangsu China

Dyness Website: https://www.dyness.com/

Dyness community: https://www.facebook.com/groups/73560020090