Dyness DH200Y Enables a Dongguan Industrial Park Achieve a “Green Transition”

-

Company News

-

2025-12-03

-

Dyness

Driven by the growing trend toward green transformation, a technology industrial park in Dongguan has deployed a 1.392MWh DH200Y liquid-cooled energy storage system from Dyness, integrated with the intelligent cloud platform. The project simultaneously enhances economic returns and power supply reliability, offering a replicable model for low-carbon park development.

Seizing Opportunities — Policy and Market Drivers

As concentrated hubs of industrial activity, energy consumption, and carbon emissions, industrial parks have become key frontlines for technological innovation, management optimization, and energy structure transformation. With the rising demand for clean electricity in technology parks, “zero-carbon parks” are becoming both an enterprise competitiveness strategy and a local government priority for energy reform.

Against this backdrop, Dyness partnered with a technology park in Dongguan, Guangdong, to jointly build a “zero-carbon” smart energy park—empowering its transition toward greener, low-carbon, and high-quality development. Notably, Dongguan has introduced a subsidy policy for user-side energy storage pilot projects: beginning the month after commissioning, project investors can receive subsidies based on actual discharge volume, capped at 3 million RMB, significantly reducing initial investment pressure and accelerating the adoption of new-type energy storage.

Core Solution: Efficient Energy Storage and Intelligent Management

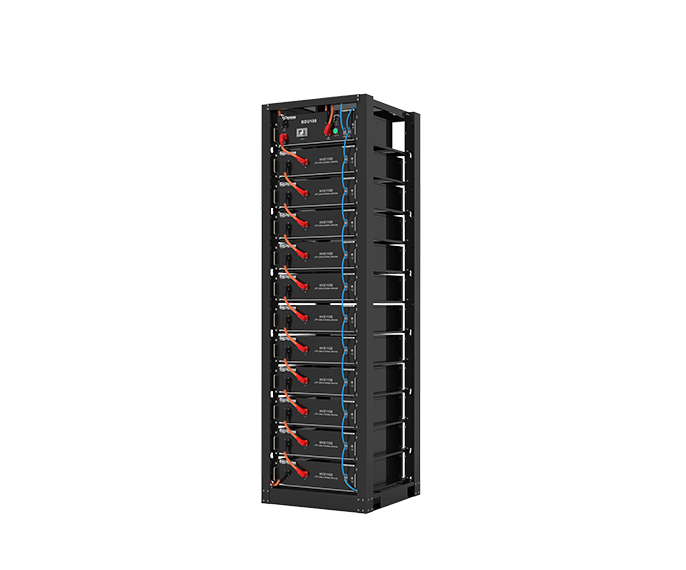

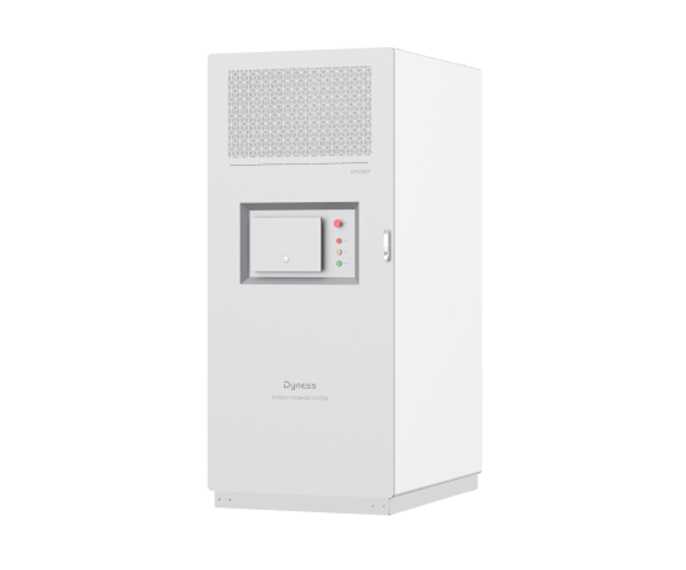

As one of Dongguan's smart manufacturing clusters, this technology industrial park attracts numerous high-end, high-growth technology innovation enterprises. The park features extensive high-load, long-cycle equipment characterized by substantial electricity consumption, significant energy fluctuations, and stringent power stability requirements. Facing growing energy demands, the client comprehensively assessed its power characteristics and operational needs before selecting Dyness' DH200Y liquid-cooled grid-connected energy storage solution. This project deployed six DH200Y liquid-cooled integrated units, forming a 0.6MW/1.392MWh energy storage system. This setup effectively alleviates peak load pressure within the park, enhances electricity utilization efficiency, and strengthens overall energy allocation capabilities.

To maximize system value, the storage facility employs dual operational strategies. The “peak-valley arbitrage” strategy stores energy during off-peak charging and discharges during peak hours, leveraging electricity price differentials to generate revenue and reduce corporate electricity costs. Concurrently, the “dynamic capacity expansion” strategy automatically adjusts the storage facility's output power in real-time based on the park's load demands, ensuring continuous and stable energy supply.

Integrated with Dyness's proprietary Energy Management System (EMS) and smart cloud platform, this system serves as a comprehensive energy control hub unifying energy storage, distributed PV, charging stations, and industrial loads. Through real-time sensing and unified coordination, it achieves dynamic optimization and collaborative control across multiple energy resources.

Beyond executing traditional peak-valley arbitrage strategies, the EMS possesses full-scenario coordination capabilities to proactively respond to regional grid demands. When facing high grid pressure, the system automatically limits charging station power, adjusts non-critical loads, and initiates energy storage discharge to alleviate grid strain. During off-peak periods, it increases charging power to absorb surplus electricity, stabilizing grid frequency while reducing the park's electricity costs—delivering dual benefits of economic savings and grid service support. Preliminary calculations indicate the project is projected to generate approximately 550,000 yuan in revenue during its first year, providing robust support for the park's energy cost control and efficiency enhancement.

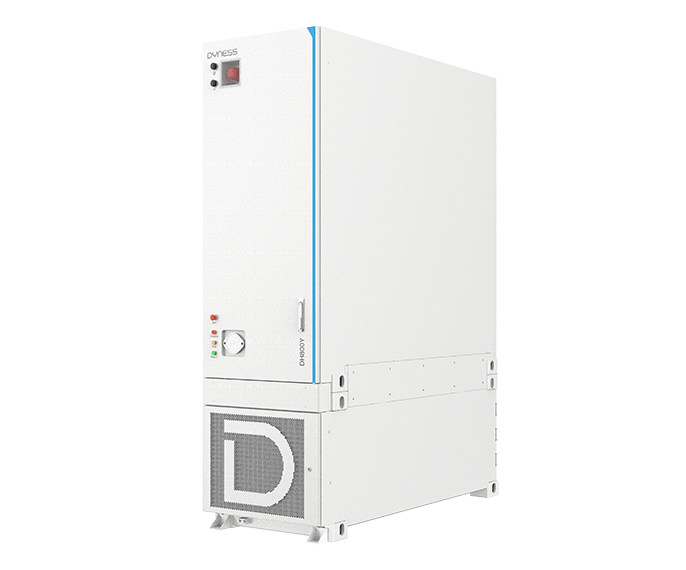

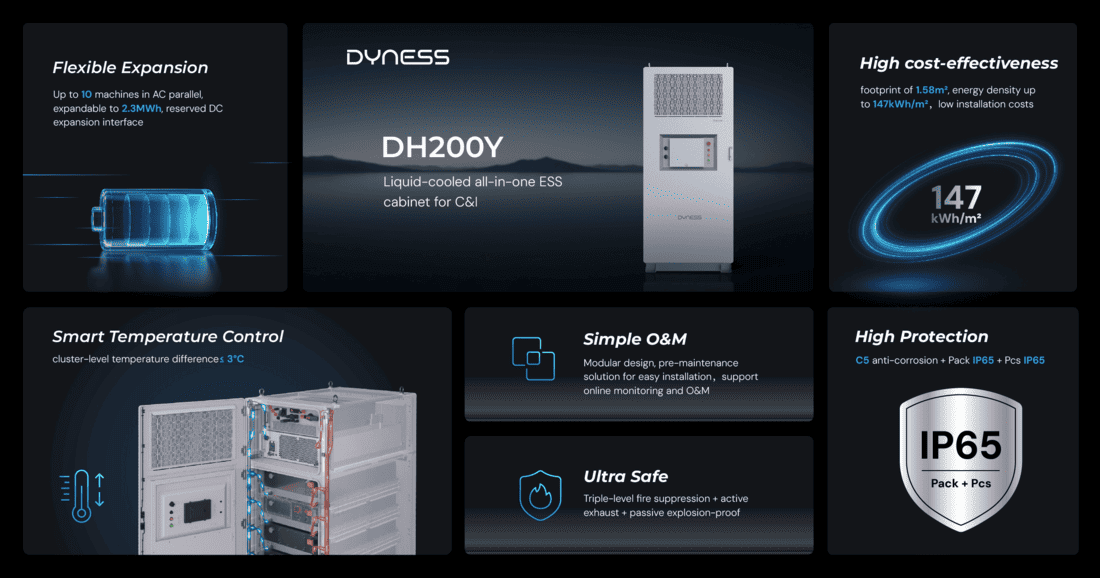

The Dyness DH200Y liquid-cooled all-in-one ESS cabinet deployed in this project boasts a single-cabinet capacity of 232kWh, supports AC parallel connection of up to 10 units, and is scalable to 2.3MWh, accommodating diverse power demand scales. Featuring a compact design with minimal footprint, it achieves an energy density of 147kWh/㎡, effectively conserving land space for customers. Regarding safety, the DH200Y incorporates pack-level cell monitoring, three-tier fire detection, and active venting with passive explosion-proof design. This comprehensive protection ensures long-term stable and secure operation. Widely applicable across grid-connected scenarios such as office parks, commercial buildings, and charging stations, it serves as an ideal choice for enterprises building efficient, reliable smart energy systems.

Pioneering Low-Carbon Park Development and Driving Green Industrial Upgrades

The successful implementation of this project not only provides the park with clean, efficient, and intelligent energy solutions but also establishes a replicable and scalable model for green and low-carbon upgrades across industrial and technology parks.

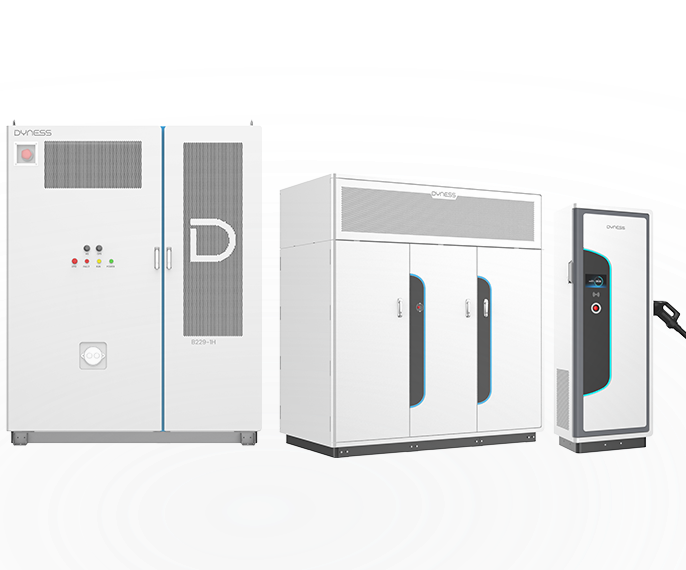

Moving forward, Dyness will continue to uphold its “customer-centric” philosophy. Leveraging its comprehensive range of energy storage products and diversified system solutions, the company will deepen the application of energy storage across more industrial and commercial scenarios, contributing to the realization of global digitalization and carbon neutrality goals.